... the other way.

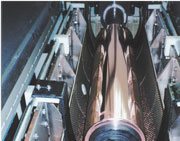

ECOPLATER COPPER COMPACT E, EC

COPPER PLATING TANK FOR ROTOGRAVURE CYLINDERS

-

-Compact design, low overall height

-

-Simple operation by GALVACONTROL

-

-Flexible cylinder holding device with ECOCLAMP or modular adapter system

-

-Can be integrated into automatic production line

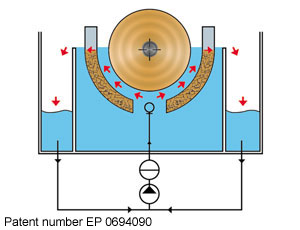

PATENTED ELECTROLYTE FLOW

-

-Symmetrical flow of electrolyte

-

-Controlled transport of anode sludge away from cylinder

-

-Optimal anode geometry

ECOPLATER produces fine crystalline hard copper layers, which are ideal conditions for the electronic engraver. This state-of-the-art machinery is based on the latest innovations in gravure cylinder copper plating. In addition, the machinery has many economical aspects, such as:

- Defined layer purity and surface quality result in low diamond wear, thereby keeping production costs low

- Efficient current transfer results in consistent layer thickness

- Low energy consumption cut production costs

ANODE SHAPE

-

-Concentric anode shape

-

-Precise electrolyte flow

ANODE ADJUSTMENT

-

-Concentric automatic anode adjustment

-

-Optimized current flow towards cylinder

ANODE BASKETS

-

-Titanium anode baskets

-

-Symmetrical overflow of electrolyte

-

-360° electrolyteoverfolw return

ECOCLAMP

-

-Lightweight cylinder holder

-

-Internal drive wheel and current transfer are bulidt into the machine

-

-Simple design with easy fit

GALVACONTROL

-

-PLC electronics with interface to remote control

-

-Fully automatic process or manual operation

-

-Adjustable production parameters

ADAPTER

-

-Weight saving construction

-

-Modular design

Plating time:

Current density:

Immersion:

Electrolyte temperature:

Copper hardness

Plating thickness tolerance:

Electrolyte filtration rate:

100 µm layer in 30 - 32 minutes

30 A/dm²

50 % of cylinder surface

30-34 °C ± 1,5 °C

HV 0,1 180-220 ±2,5 HV (with additive)

for 100 µm layer ± 3%

approx. 15 times per hour

News

Machines

Automatisation

Grinding and Polishing

Copper Plating

Chrome Plating

Preparation

Quality Control